Steel pickling is metal surface treatment used to remove impurities, rust and scale from the surface of the material.

During hot working processes, an oxide layer (referred to as “scale”, due to the scaly nature of its appearance) develops on the surface of the metal. Before most cold rolling processes, previously hot rolled steel goes through a pickling line to remove the scale from the surface and make it easier to work. To restore the best corrosion resistant performance, the damaged metal layer must be removed, exposing a fully alloyed stainless steel surface.

The continuous hydrochloric acid pickling process is adopted to remove the iron oxide layer on the surface of the hot-rolled steel strip and cut off the irregular edges of the steel strip to provide qualified hot-rolled steel materials for the next process. The steel strip after pickling has a pure iron surface and can be cold rolled or hot-dipped galvanized.

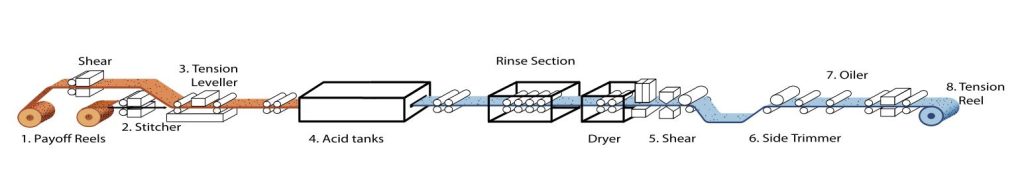

Process of steel pickle line:

1) The hot rolled coil enters the pickle line on one of two payoff reels.

2) The end of one coil is joined with the beginning of the next coil at the stitcher. Connecting the end of one coil with the beginning of another allows for continuous operation of the pickle line.

3) The band passes through the tension leveller which flattens the strip and mechanically breaks up surface defects.

4) The band of steel is run through a series of acid tanks to remove rust and other impurities. After the acid bath, the band is rinsed in hot water to remove the last of the acid.

5) The band then runs through a shear, which cuts out the stitch that connected the two coils at the beginning of the pickle line. The band must be separated after it is cleaned so each individual coil can be re-coiled.

6) The sides of the band are trimmed to the customer's specified width.

7) The band can be coated with oil.

8) The tension reel re-coils the steel so it's ready for the next step.

Our factory focus on design and manufacture mandrel, tension reel, payoff reel for steel and non-ferrous metals rolling mill and coil processing lines, such as continuous pickling line, continuous galvanizing line, annealing line, slitting line, cut to length line,color coating line, tension leveling line, rewinding line, trimming line etc. Any needs, contact us!