Product description:

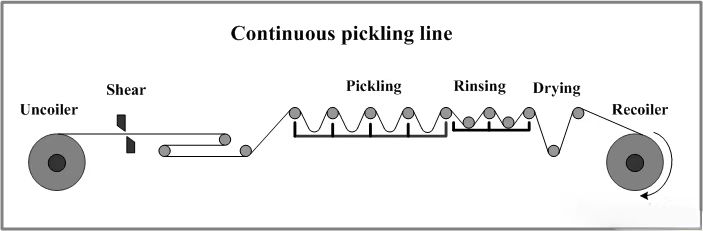

uncoiler located at the entry side of steel pickling line. Steel pickling line refers to a treatment that is used to remove impurities, rust, and scale from the surface of a material. During hot working processes, an oxide layer (referred to as “scale”, due to the scaly nature of its appearance) develops on the surface of the metal. Before most cold rolling processes, previously hot rolled steel goes through a pickling line to remove the scale from the surface and make it easier to work.

Steel pickling line refers to a treatment that is used to remove impurities, rust, and scale from the surface of a material. During hot working processes, an oxide layer (referred to as “scale”, due to the scaly nature of its appearance) develops on the surface of the metal. Before most cold rolling processes, previously hot rolled steel goes through a pickling line to remove the scale from the surface and make it easier to work.

Uncoiler is located at the entry of the steel picking line and holds the coil on the mandrel. When the mandrel expands and rotates, the uncoiler tightens the coil and unwinds the strip to the next equipment.

Recoiler is located at the delivery of the production line and winds the strip to form coils. The collapsible mandrel of the tension reel winds the coil tightly while supplying the required tension during line operation. The force needed to do this is much higher than with uncoiler.

OEM

As specialist on mandrels, recoiler, and uncoiler, our products won a good reputation. If you are looking to work with a management team that brings years of perspective to your engineering partner relationship and broad experience to your project, BONIETO has that team. We could give customized solutions to your industry. We seek to build long-lasting partnerships, we will help you to concentrate on your core business. Our products and services will support you.