Product description:

customized slitting line uncoiler.

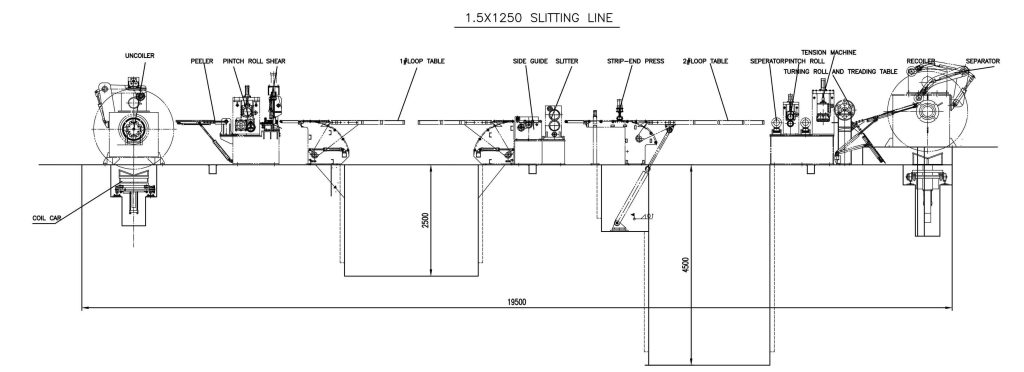

The tension reel and pay-off reel are applied to copper, aluminum, steel cold and hot rolling mill, and coil processing lines, such as continuous pickling line, continuous galvanizing line, annealing line, slitting line, cut to length line,color coating line, tension leveling line, rewinding line, trimming line etc.

Parameters:

Coil material – aluminum and aluminum alloy

Strip Width – 2200mm

Strip Thickness – 0.4~3mm;

Coil Weight – Max 20T

Working speed – max 200m/min, min 100m/min

Stub type slitting line uncoiler, payoff reels, works for aluminum and aluminum alloy slitting line;

Parameters:

We could manufacture different type of uncoiler, payoff reel for slitting line. also recoiler, mandrel & spare parts.

The recoiler and uncoiler are applied to steel, aluminum, steel cold and hot rolling mill, and coil processing lines, such as continuous pickling line, galvanizing line, annealing line, slitting line, cut to length line, color coating line, skin pass mill,etc;

The uncoiler is located at the entry of the production line and holds the coil on the mandrel. When the mandrel expands and rotates, the uncoiler tightens the coil and unwinds the strip to the next equipment. During the line operation it feeds the strip continuously while applying back tension.

The recoiler is located at the delivery of the production line and winds the strip/plate to form coils. The collapsible mandrel of the recoiler winds the coil tightly while supplying the required tension during line operation.

The recoiler and uncoiler contains mandrel,gearbox,base frame,motor and coupling,brake,traversing and centering mechanism,hydraulic and lubrication mechanism.

OEM

We could design and manufacture according to specific needs;could also machining as customer’s drawing; Any needs,contact us!